The technique will remove rare metals from the design and use a green, non-corrosive electrolyte which can be adjusted to suit specific types of wastewater.

The project aims to develop products which can be manufactured at scale and reduced costs, for a range of applications. These prototypes will allow less pure water, like rainwater, storm overflow and industrial process wastewater to be used as feedstock, reducing input costs and widening the potential locations where green hydrogen could be produced.

Using industrial process wastewater could also encourage colocation of production sites, using wastewater to generate hydrogen that powers the onsite process itself. This offers a closed-loop solution, further enhancing the environmental and financial benefits.

Developing smart injection strategies that benefit sensitive users, be that hydrogen or natural gas customers, will also be a key feature of the project. Injecting hydrogen at strategic nodes along the gas network will allow distribution networks to better control pressure tiers and effectively target early adopters of hydrogen blends, whilst protecting sensitive users. It could reduce operational constraints and increase resilience in the transition to net zero.

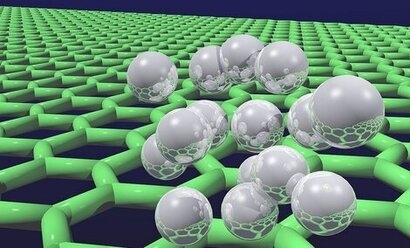

Hydrogen is considered green when it is produced from renewable power from wind or sunshine through electrolysis. Green hydrogen can play a role in energy, transport, heat provision, and hard-to-decarbonise industries, replacing natural gas and other fossil fuels.

“Low-carbon hydrogen has the potential to benefit numerous areas like industry, residential heating, transport, and electricity production” said Charlie Newbold, Head of Operations at Hydrostar. “However, the associated costs and demand for highly purified water are currently a major hurdle for adopting widespread commercial hydrogen production. Our focus will be tackling these specific challenges, aiming to make low-carbon hydrogen a more feasible low-carbon energy option across these sectors."

For additional information: