Mercedes Benz/Daimler is aiming for a future in which the transportation of goods and people is totally free of emissions. To this end, the company has introduced a range of commercial electric vehicles with plans to launch them in the market at various stages over the next decade.

Daimler Trucks has introduced the Mercedes-Benz Urban eTruck, an emission-free ton truck for heavy duty distribution with a range of approximately 200 kilometers and the company is aiming for an official market launch at some point early in the next decade. Meanwhile, Mercedes-Benz Vans is aiming to launch a series-production van with electric drive while the company also has plans for production of an electric city bus.

“At the last IAA Commercial Vehicles, we focused on long-distance transport: With our Mercedes-Benz Future Truck 2025, we were the first to show the world that autonomous trucks will make long-distance transport safer and more efficient” said Dr. Wolfgang Bernhard, Member of the Board of Management of Daimler AG, responsible for Daimler Trucks & Buses. “At this year’s IAA, our focus is on cities: we are presenting our vision of urban transport. Just like with long-distance haulage, our goal is to achieve more safety and efficiency than ever before – and also to be free of local emissions. This will make our cities even more pleasant to live in, despite rising populations and an increased need for transportation.”

The Future Bus

According to estimates by the United Nations, about 70 percent of the world’s population will live in urban areas by 2050. This will increase the need for mobility and the transport of goods. At the same time, people’s expectation of quality of life in the cities are also rising. This involves a number of challenges – with regard to traffic density, air quality and noise levels.

Daimler’s commercial vehicle divisions are aiming to meet these challenges with autonomous driving, the systematic further development of electric drive towards series maturity, and full connectivity. The first step is the further development of a Highway Pilot for autonomous driving, especially in big cities. The partially autonomous Mercedes-Benz Future Bus with CityPilot can drive at speeds up to 70 km/h on so-called bus rapid transit (BRT) routes, stops to the nearest centimetre at bus stops and traffic lights, sets off automatically, passes through tunnels, brakes for obstacles or pedestrians on the road, and communicates with traffic signals. The driver is on board and monitors the system, but his or her work is much easier. The Future Bus is equipped with long- and short-distance radar, a large number of cameras and a GPS satellite navigation system. The intelligent connectivity between the cameras and sensors is pioneering. They deliver a precise picture of the surroundings and the exact position of the bus.

According to Hartmut Schick, Head of Daimler Buses, the partially autonomous Future Bus will be the first city bus that can drive in automated mode in real traffic situations. CityPilot will make traveling by bus in the city even safer, more comfortable and significantly more efficient. The company intends to invest about 200 million euros in the further development of its city-bus portfolio in the next five years, aiming to put CityPilot into series production early in the next decade.

In parallel, Daimler Buses is working systematically on the introduction of a fully electric city bus. The market launch of the Citaro with electric drive is planned for the year 2018. Thanks to the ongoing rapid development of battery technology with regard to capacity, Daimler engineers anticipate a range of approximately 300 kilometres in the year 2025 – sufficient for most bus routes – even in the most unfavourable climatic conditions of minus 20 degrees Celsius in winter and plus 40 degrees Celsius in summer.

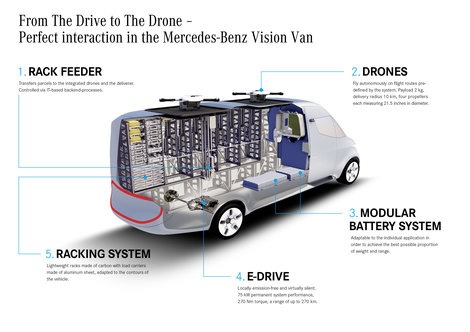

The new Vision Van study vehicle also features electric drive. It has a 75 kW electric drive system with a range of 80 kilometres to 270 kilometres, depending on application, so deliveries with the Vision Van do not cause any local emissions. They will also be almost silent with regard to noise pollution issues. Mercedes-Benz put the first electric van, the Vito E-Cell, into series production in 2011. Approximately 1,000 of them have been delivered to customers in Europe enabling the company to acquire important experience with electric models in daily use.

The Vision Van is the world’s first van to feature a fully automatic loading space and integrated delivery drones. For example, when the driver stops the vehicle in a residential area and delivers some parcels manually, other parcels can be delivered at the same time by air to their recipients – even if they are not at home. This will reduce delivery times and offer completely new possibilities for the end customer, such as the direct delivery of goods at an agreed time on the day they are ordered. Mercedes-Benz Vans anticipates efficiency increases of up to 50 for the last mile.

The Vision Van is the world’s first van to feature a fully automatic loading space and integrated delivery drones. For example, when the driver stops the vehicle in a residential area and delivers some parcels manually, other parcels can be delivered at the same time by air to their recipients – even if they are not at home. This will reduce delivery times and offer completely new possibilities for the end customer, such as the direct delivery of goods at an agreed time on the day they are ordered. Mercedes-Benz Vans anticipates efficiency increases of up to 50 for the last mile.

Like the Mercedes-Benz Vision Van, the Urban eTruck also delivers its goods to supermarkets in inner cities free of local emissions and quietly. The fully electric truck for urban distribution transport with a gross vehicle weight of up to 26 tons has a battery pack with a total capacity of 212 kilowatt hours, allowing a range of approximately 200 kilometres. This technology could conceivable be launched on the market early in the next decade.

The triple-axle vehicle with a permissible gross weight of 26.0 t produces zero local emissions and runs silently, yet it is equal to a truck with an internal combustion engine in terms of load and performance, and, thanks to its innovative power supply, it is also economical. The outstanding features of the Urban eTruck include its drive with electrically powered rear axle and electric motors directly adjacent to the wheel hubs. Their maximum output is 2 x 125 kW, while torque is 2 x 500 Nm. The standard version of the axle has already proven itself in buses.

The battery capacity of the Urban eTruck has a modular design. The basic arrangement is a battery pack consisting of lithium-ion batteries with a total capacity of 212 kWh. This results in a range of up to 200 km – normally enough for a typical day's delivery round.

The Urban eTruck can operate in three different modes, which optimise the way in which it is driven and the use of the energy available. On a standard journey, the Urban eTruck is set to 'auto'. It automatically adapts the 'auto', 'agile' and 'eco' settings to conditions within a certain target range. For special cases there is a power mode called 'agile', and for maximum range there is an 'eco' mode.

A tablet provides the driver with additional information about the trip, as well as continually updated and precise details on range and batteries. These are presented on a local map with a clever graphic known as the 'range potato' and a target range. The calculations are based on the driving strategy, the three-dimensional map and the trip planning.

“Until now, the application of electric drive systems in trucks has been extremely limited” added Dr Bernhard. “But meanwhile, batteries’ costs, capacities and charging times are improving rapidly. So we anticipate the market launch of electric drive in heavy-duty distribution transport early in the next decade. We intend to push electric driving as effectively as we did with autonomous and connected driving.”

Until recently, the use of fully electric drive systems in trucks seemed impossible – mainly due to the high costs of batteries in combination with the vehicles’ low range. However, the technology is now significantly more mature. Battery cells in particular are rapidly improving: Daimler Trucks expects the cost of the batteries of a fully electric truck to fall by a factor of 2.5 between 1997 and 2025 – from 500 euros per kilowatt hour to 200 euros per kWh. Over the same period, batteries’ energy density will rise by the same factor from 80 watt hours per kilogram to 200 Wh/kg.

In parallel to this hardware in the form of autonomous or electric trucks, Daimler’s commercial vehicle divisions will also offer their customers a broad range of connected services and mobility concepts. In the future, the flow of goods will be reflected in real time by a flow of data on the Internet. As a result, journeys without loads will be minimized and waiting times while loading and the use of resources will be significantly reduced. This will increase the efficiency of the entire transport process – from production to consumption. A total of approximately 400,000 Daimler commercial vehicles are already connected with the Internet. By the year 2020, Daimler Trucks will invest about half a billion euros to connect its trucks with their Daimler Communications, surroundings and to develop specific new applications. This will increase the efficiency of its customers’ operations and will make their businesses safer and more environmentally friendly.

For additional information: