Responsibility for preventing agricultural biogas plants from causing hazards for the safety and health of workers and the general public rests solely with the plant operator. However, stakeholders tend to underestimate the scope and the complexity of the necessary safety precautions. As a result, explosion protection measures, emergency response plans and escape routes may have major weaknesses. The liability risks involved should also not be underestimated.

In late 2009, a study carried out by the Commission for Plant Safety (German Environment Ministry) revealed that the inspectors, including TÜV SÜD experts, found critical safety flaws in over 60 per cent of the biogas facilities examined. Weaknesses were not limited to the gas and ventilation systems or the explosion protection systems and measures, but also affected component design, structural engineering and organisational processes.

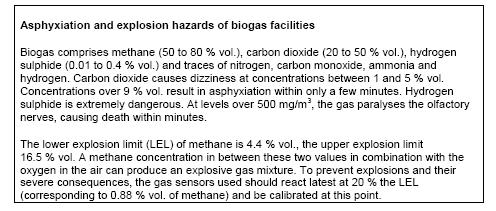

Biogas plants process large quantities of combustible and toxic gases which pose increased fire, explosion or asphyxiation hazards in case of faults in design, materials or control. In the event of an incident at the plant, people may be injured, property damaged and the environment (air and water) polluted.

Tailored safety solutions

As the responsibility for ensuring the safety of biogas facilities rests with the operators, they must assess the possible hazards in accordance with the applicable legislation (for example the Ordinance on Industrial Safety and Health, the Occupational Safety Act, the Dangerous Substances Regulation) and implement appropriate safety measures. First and foremost, the safety of the electrical, gas and pressure systems must be taken into consideration. However, fire, lightning and explosion protection and taking precautions to ensure protection against health hazards and environmental pollution also play a central role. Plant operators, for instance, must create an explosion protection document, systematically assessing explosion hazards.

Safety equipment (suitability, wiring) and the planning of the building and technical systems (material selection and design) must be tailored to the specific plant and inspected at regular intervals. Extraction systems, also those installed outside the biogas plant, reliably prevent incidents such as leaking of toxic gases. Operators failing to fulfil their obligations run the risk that their plants no longer comply with the legal requirements, which may result in the shutdown of the plant or loss of insurance cover.

Organisational measures

However, operators should not focus solely on installation-related safety precautions, but should also take into account organisational measures which are frequently neglected in practice. These include intelligently designed emergency response plans and escape routes. To ensure an effective emergency response system, the sensors (gas and fire detectors) must be appropriately positioned, calibrated, wired and maintained. For larger plants, recurrent emergency drills and exercises show whether the alarm is able to alert all persons in and around the facility at all times and prove the efficiency of escape and rescue plans.

The same applies to the escape routes: the emergency lighting must be independent from the mains power supply and explosion-proof and the escape route must be extensively signposted (as per BGV A8). In addition, manually operated doors may only open in the direction of escape and lockable doors. Escape routes should be provided with anti-panic locks so that they can still be opened from the inside when locked. Apart from the above, discussing and coordinating the rescue and escape plans with the local fire service is also highly advisable.

Expert support

To minimise economic liability risks, companies such as TÜV SÜD provide assistance to the operators of biogas plants from the planning stage to construction and operation. The experts verify constructional, technical and organisational safety systems and measures, check the selected materials and their properties and also review emergency response plans and escape routes.

Editor's note: Many thanks to Johannes Steiglechner from TÜV SÜD Industrie Service GmbH for kindly providing this piece. His company provides support with initial and recurrent inspections, compliance with legal regulations and assessment of the safety and environmental compatibility of biogas plants.

For additional information: