Reductions in the electricity generation costs for photovoltaics can be reached through two mechanisms: improving the efficiency of solar cells and reducing their production costs. With advanced processes for metallization of solar cells, both effects can be reached at the same time, reveals Fraunhofer ISE’s ETAlab, which has been working to develop solar cell contact technologies.

In a recent press release, the laboratory revealed it had developed an advanced metallisation process enabling solar cell contacts to be solely produced using low-cost materials, such as copper. In doing so, industrially feasible galvanic processes were used and expensive silver has been replaced.

In the current standard process, silver-based pastes are used to create relatively broad and porous solar cell contacts via screen printing. Copper however can be deposited from chemical solutions in galvanic processes, which are economical and have high rates of deposition.

“With the enormous cost difference between silver and copper, simply by changing the material and keeping the efficiency the same, it is made possible to reduce the production costs by about 8 cent/WP, or in other words, by up to 10 percent,” estimates the ETAlab.

Competitive cell efficiencies

What is especially remarkable about the work of the ETAlab’s researchers though is that as well as cutting production costs, they have also achieved a solar cell efficiency of 21.4% (confirmed by CalLab PV Cells at Fraunhofer ISE) using this approach, which is comparable with values from solar cells using a highly efficient titanium/palladium/silver contact system, which must be created in comparatively expensive vacuum laboratory processes.

“Our copper-metallized solar cells from the ETAlab are not only comparable with the efficiency of the titanium/palladium/silver reference technology, but also show an excellent stability in long-term tests. A thermal stress test of 1600 hours at 200 °C had no consequences for the efficiency”, explains Jonas Bartsch, Team Leader of Plating Process Technology.

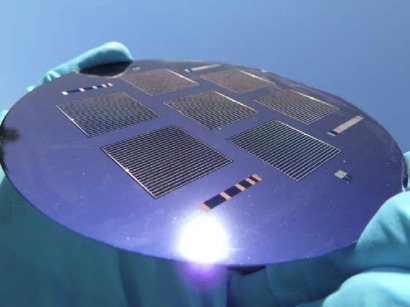

With the process knowledge built up at Fraunhofer ISE, the researchers at the ETAlab are now working on transferring this technology to large solar cell formats. “The metallization based on copper and nickel offers a significant potential for cost savings for the next generation of silicon solar cells, and with it for power from sunlight”, concludes Dr. Markus Glatthaar, Head of the Advanced Processes Group.

For additional information: