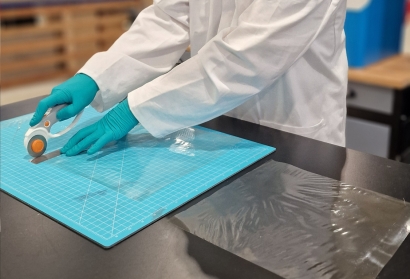

At the core of every low‑temperature water‑electrolysis system lies the membrane, a critical component for efficiency, safety, and scalability. HYScale coordinator Cutting‑Edge Nanomaterials GmbH (CENmat) has now successfully upscaled the synthesis and casting of its proprietary AionFLX™ anion exchange membranes (AEMs). The new process delivers:

“We have moved beyond laboratory production; membranes are no longer the bottleneck,” said Dr. Julien Fage, polymer chemist and project coordinator at CENmat. “This scalability opens the door to multi‑kilowatt and soon multi‑megawatt systems.”

Building on the membrane advance, HYScale partners have fabricated large area, critical-raw-material free catalyst coated substrates (CCSs) for both anode and cathode, ensuring that all primary stack materials are available at industrial scale and meet stringent performance targets.

To verify real world functionality, researchers at the National Research Council of Italy (CNR) designed, built, and operated a 6 kW AEM short stack using the new membranes and CCSs. The stack demonstrated stable operation across a wide range of temperatures, and current densities; proof that HYScale’s materials can be combined into robust, application ready membrane electrode assemblies (MEAs).

Leveraging data from the short stack tests, the German Aerospace Center (DLR) has finalised the digital design of a 100 kW HYScale stack demonstrator. The model details dimensioning and material selection, providing a firm blueprint for construction and paving the way to Technology Readiness Level 5 (TRL 5).

“HYScale is uniquely positioned to deliver scalable, mass‑manufacturable solutions for green hydrogen,” said Jagoda Manss‑Chmielarz, R&D engineer at DLR. “Our focus is not only on better materials, but on making them work in real‑life production environments.”

Taken together, these achievements trace a clear progression: