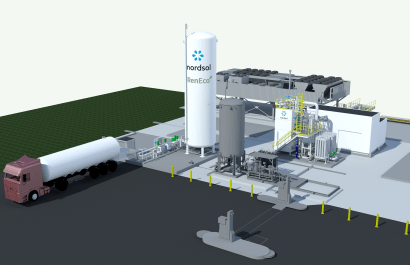

Leveraging Nordsol's innovative technology, RenEco will convert biogas into bio-LNG (liquefied biomethane), with production to commence in the first quarter of 2024.

Bio-LNG is positioned to play a pivotal role in the sustainable transformation of long-haul road and maritime transport. Its advantages over diesel are manifest in significantly reduced emissions of CO2, NOx, SOx, and particulate matter. Depending on the feedstock, bio-LNG is carbon neutral or even carbon negative.

“Bio-LNG is the best solution for decarbonizing the hard-to-abate long-haul transport sector today,” said Léon van Bossum, CEO of Nordsol. "With this inaugural production plant in the UK we demonstrate that onsite biogas liquefaction to bio-LNG is not only sustainable but also affordable and scalable.”

Anticipated to yield 3.4 kilotons of bio-LNG annually, this facility will fuel over 8 million miles (13 million kilometers) of fossil-free road transport for heavy-duty trucks. The plant stands as an integral component of a rapidly developing circular economy.

RenEco's initiative involves the collection of organic waste from all parts of the food supply chain, its conversion into biogas and organic fertilizers via anaerobic digestion, and the transformation of biogas into the renewable products bio-LNG and biogenic CO2. While the biogenic CO2 displaces fossil CO2 in various industries, RenEco's fleet, along with their customer’s fleets, will run on sustainable bio-LNG creating a circular supply chain.

William Wykes, director of RenEco, said, “After extensive market research investigating how to decarbonize both our own HGV fleet and our retail customers’ fleets, Nordsol was chosen as a long-term partner to provide their liquefaction technology.”

Given the growing demand within the transportation sector, bio-LNG's economic viability is increasingly appealing to biogas producers. Simultaneously, Nordsol's innovative, highly integrated production process ensures a cost-effective conversion of biogas into bio-LNG and biogenic CO2. The Rushden facility is the inaugural step in a broader strategy to establish multiple bio-LNG plants across the UK, underscoring Nordsol's dedicated organizational support for the transition from biogas to bioLNG in the UK.

Wykes continued, “Phase one of the bio-liquefaction facility will produce enough bio-LNG to fuel 100 HGVs operating 24 hours per day 7 days per week. This investment is part of a combination of initiatives RenEco is undertaking designed to direct the biogas produced onsite away from renewable heat and power to instead produce products for customers that directly replace traditional fossil-derived products which are typically more challenging to displace.”

van Bossum added, “We believe in the urgency of the present – bio-LNG is now – because we recognize the immediate need to bring back carbon emissions. We are fully committed to our vision; we plan to double the capacity of this plant in 2025.”