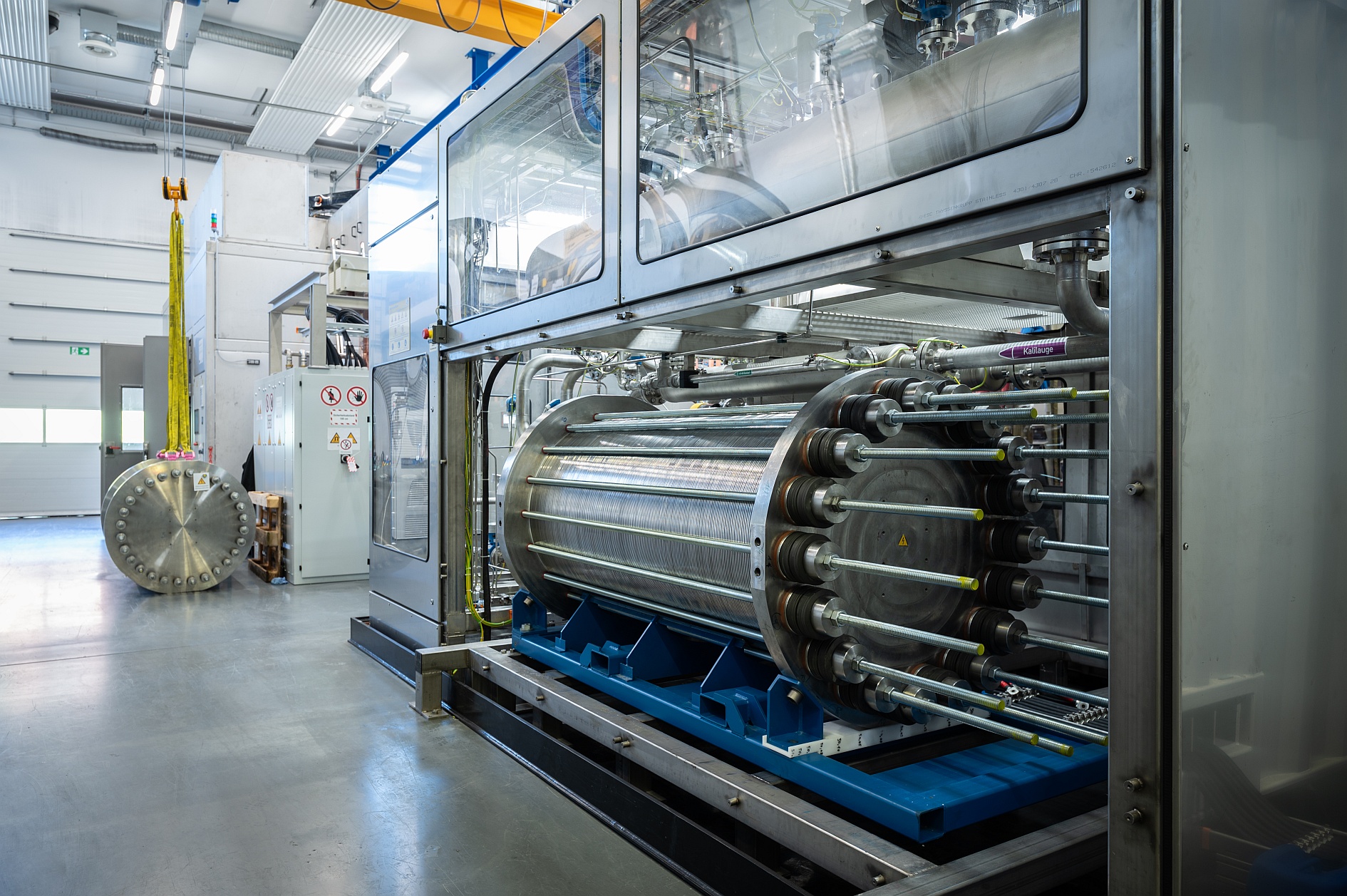

The aim is the economical series production of high-efficiency electrolysis stacks. As a core component in the production of green hydrogen, the stack has a decisive influence on the efficiency of the overall system.

At the beginning of 2022, Ecoclean and the ZSW began developing an internationally competitive electrolysis system for the production of green hydrogen as part of the "EcoLyzer BW" joint project. The result is EcoLyzer, a modular concept for the cost-efficient construction of electrolysis plants with a system output of 1 to 20 MW in the vicinity of energy producers (solar, wind, water). Series production started at Ecoclean at the beginning of 2024.

Electrolysis stack - core component for high system efficiency

The scientists at ZSW and the engineers at the plant manufacturer are once again pooling their expertise to produce the heart of the scalable electrolysers, the electrolysis stacks, in an economically industrialised manner in-house.

Manfred Hermanns, Director Sales & Customer Services at Ecoclean GmbH, cites various reasons for this, "The quality and efficiency of the stack have the greatest influence on the efficiency of the overall system. The more efficiently it works, the more hydrogen is produced from the amount of electricity used.

"As the production costs of hydrogen are around 80 % dependent on the price of electricity, the efficiency of the stack has a decisive influence on the price of hydrogen."

The manager sees a further contribution to improved cost efficiency in green hydrogen production in the economical, automated production of the stacks, which consist of a large number of individual cells connected in series and other components.

"As an experienced machine and plant manufacturer, we have the know-how and expertise to efficiently automate even complex production processes and thus both reduce the production costs of the systems and ensure a high level of quality," adds Hermanns.

Last but not least, the production location is playing an increasingly important role in the current geopolitical situation. On the one hand, it is a question of where a product is developed and manufactured.

"Engineered and made in Germany" are still good arguments here, as Hermanns confirms, "Customers are increasingly asking us where we source our components from and about the ecological footprint of our systems and equipment. We can answer these questions satisfactorily by developing and manufacturing in Germany."

In addition, companies are being asked more than ever to ensure a resilient and traceable supply chain that is permanently independent of long transport routes and customs duties. What's more, industrial companies, local authorities and energy suppliers are increasingly having to source products from Europe if they want to receive funding for projects.

Scalable solution that works without critical raw materials

Technologically, the EcoLyzers are based on a system technology for alkaline electrolysis developed and continuously optimised by ZSW over the last decade. The process is industrially established and scores highly in comparison to other electrolysis processes due to its low investment costs. In addition, this technology does not require any resource-critical raw materials such as rare earths and precious metals to produce hydrogen.